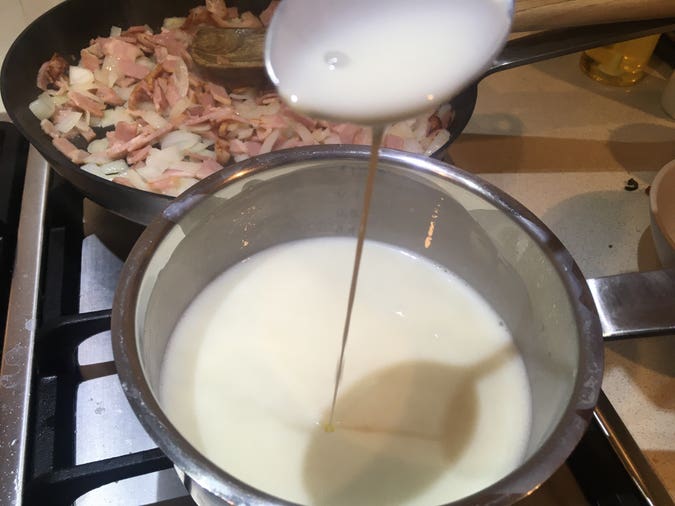

macaroni cheese with cheat’s béchamel and toasted breadcrumbs

ruby saw our macaroni cheese recipe and suggested we add toasted panko breadcrumbs, smoked paprika, and fried carrot and spinach leaves in the pot towards the end. we tried the first two this time, and i think it went pretty well!

(with shark + luca)

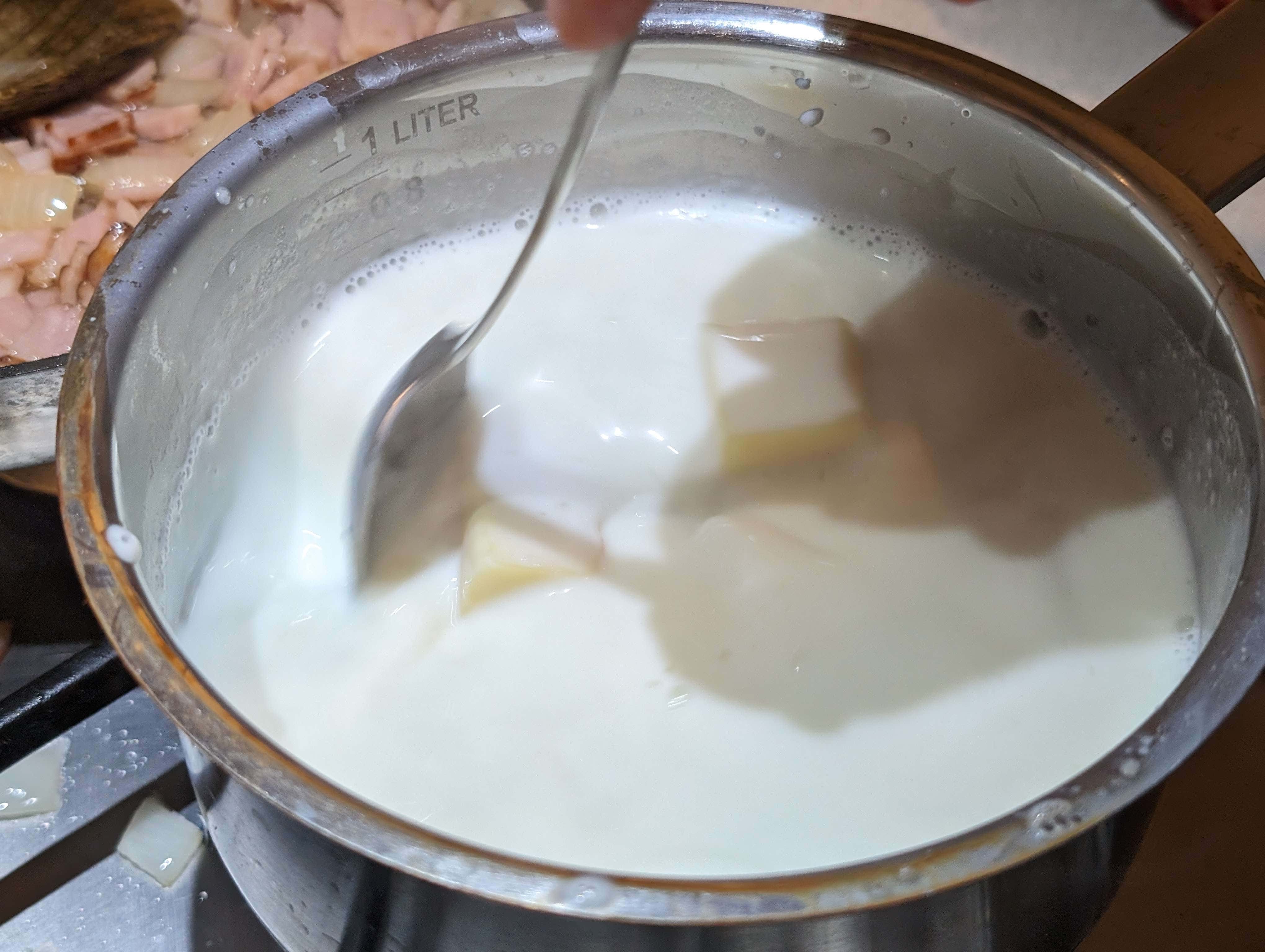

i gave it a go today with all of my proposed additions and yeah. this slaps. only problem is that i misread the steps with adding the cornflour - i added it to the pot of milk and went “well what do i do with the reserved milk then?” and just dumped that milk in after, which was probably suboptimal. sauce came out a little grainy. also i scaled the recipe down a little too much and probably didn’t have enough sauce too.

BUT! it is very good. and my additions are also very good.